Value-add customization and support.

From design to production, our custom mold making capabilities are aligned with your unique project needs. Our team is dedicated to helping you improve your project outcome by adding value at every stage of the process.

Mold making is the critical first step of many manufacturing processes, creating the template that will be used for the product or packaging unit to come.

Custom Mold Making Process

Design Input

Before we can begin manufacturing any product or packaging, we work with you to settle on a manufacturable design. In some cases, clients come to us with a concrete idea of what they’re looking for, but that isn’t always the case.

When you need guidance, our team of experts will work with you to find the most effective way to bring your project to life. We offer best practices, suggestions, and support in deciding how to manufacture your product or packaging while adding value to the end result.

Manufacturing

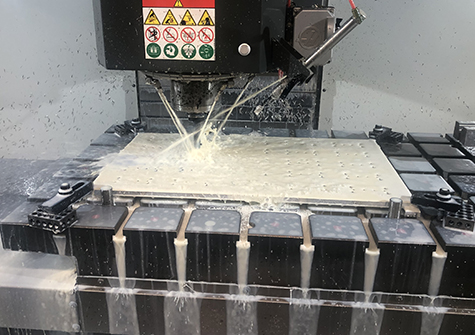

Once the design is settled, our engineering team machines the mold, typically using high-quality aluminum. Utilizing 3 and 4 axis CNC machining centers, the mold is created in-house.

Keeping our operations vertically integrated, meaning that everything is done within our facilities, cuts down the time it takes to get your molds ready for use.

Mold Making For Your Industry

Janco serves clients across a range of industries and sectors, including:

Common projects that utilize mold making capabilities include insoles and other athletic gear, surgical trays, clamshells, blister packs, and more.

Need a team that will handle all of your mold making needs with innovative technology

and ongoing support? We’re here to help.

Capabilities Form

"*" indicates required fields